Paper And Boxes

We manufacture high-quality paper and board that exemplify strength and stiffness.

Our products include:

- Flouting Paper

- Flouting Paper

- Kraft Paper

- Boxboard

Corrugated Boxes

We design custom corrugated boxes tailored to our customers' specific requirements. Our strong backward integration ensures quick access to raw materials, enhancing our value chain and accelerating delivery times.

Guidance For Customer About And Various Types Of Cartons

This section is designed to help you choose the right box for your shipping and packing needs.

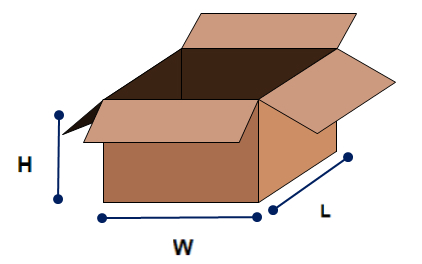

Measurements

Unless otherwise stated, box sizes are computed using inner dimensions. The inner box’s dimensions are really determined by the size of your contents. Typically, these measurements are stated in the following order: length (L), width (W) and height(H).

The aperture of a constructed box serves as the basis for dimensions. The length of the aperture is defined as the longer of the two sides. The “width” is the shorter of the two sides. The “height” of the box is the side that is parallel to the length and breadth.

How To Measure A Box – The Quick Way

Start by measuring the longest or lengthiest panel while keeping an eye on the box’s opening. Measure from left to right using a tape measure while inserting it into the bottom of the box about an inch from the back wall.

For the panel with a smaller width, repeat the procedure. The tape measure should then be placed at the end of a side flap that has been folded inward so that it is parallel to the box’s vertical side wall before being extended downward until it rests on the inner flap at the box’s base. You will learn the box’s depth with this practise.

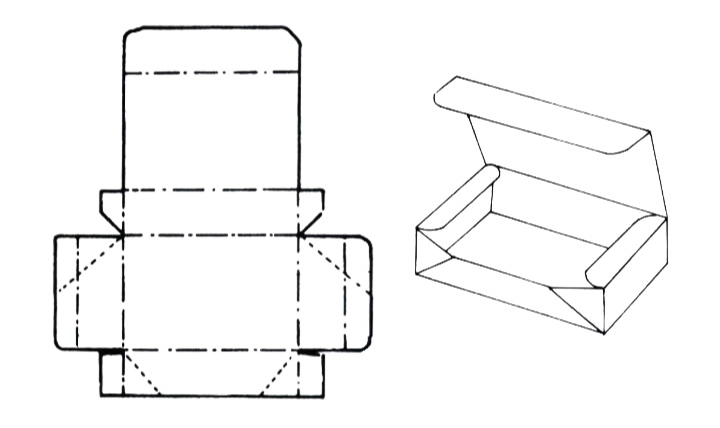

One Piece, Die-Cut Boxes

When completed, one-piece Die-Cut boxes without flaps, such the “mailer-style” with a tuck-in top, don’t have flaps, but the measurement process is essentially the same.

Use the inside rear panel, since it has a visible Score line, to determine the box depth (crease separating back panel from lid). Measure between the Score lines on the inside of the top or lid to determine the breadth of a die-cut box. Place your measuring device on the bottom of the box about an inch from the rear panel to determine the box’s length. From left to right, count.

Box Construction – What You Need To Know

The two ends of the side panels connect at the “Manufacturer’s Joint” to form the box. The panels are then adhered to one another with glue, tape, or staples. Regular slotted shipping cartons fall inside the scope of this description (RSCs).

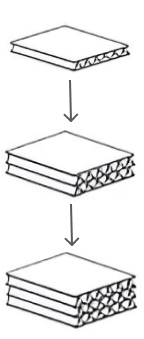

The manufacturer’s joint seal’s kind is determined by the side panel’s thickness and content weight. For instance, most single wall boxes are made with glue, but some double wall and most triple wall boxes are made with staples. Die-Cut boxes, however, are made of single-piece panels. jointly scored and folded. There is no manufacturer’s joint there.

Box Strength

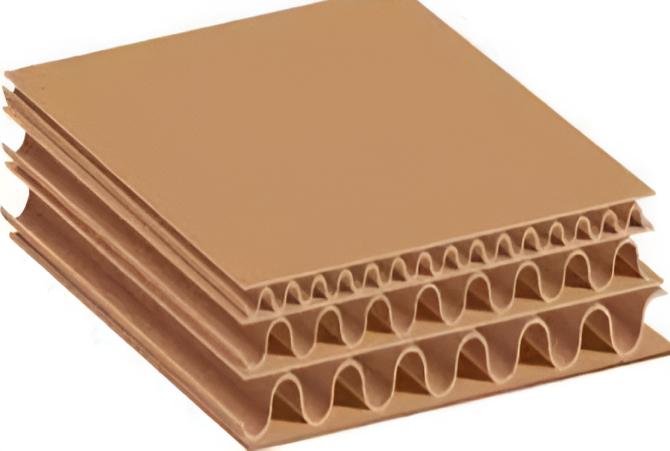

A corrugated box’s strength begins with the material used to make it. Linerboard and medium are the two main parts of a corrugated sheet. The flat paper that covers both sides of the sheet is called linerboard, and the paper that is “fluted” or curved is called the medium.

The flute resists bending and pressure from all sides when it is attached to the linerboards with a starch-based adhesive. The flutes create vertical columns that can sustain heavy loads when they are positioned vertically on their ends.

Flutes are available in five standard heights and forms; the most popular ones are “B-flute” and “C-flute” (used for Die-Cut boxes) (used for RSCs). Contrary to appearances, B-flute is compressed and seems thinner. To give better side wall protection from impacts and punctures, it is created with additional paper. C-flute has more stacking strength but is higher and has more air gap. Consider E-flute if you want superb graphic reproduction.

Look For Manufactures Stamp

Look for the Manufacturer’s Certification Stamp, which is often placed on one of the bottom flaps of the box, to confirm that the material of the box you’re buying complies with industry requirements. The material is designated as “singlewall,” “doublewall,” or “triplewall” on the stamp. It also validates the Edge Crush Test or the Mullen Bursting Test, the latter of which is most frequently 200 pounds per square inch (ECT 32 lbs. per inch). Corrugated linerboard’s bursting strength is determined by the Mullen Test, while its stacking strength is determined by the Edge Crush Test. The 200 lbs. Mullen box and the 32 ECT box are comparable in stacking strength. But that is where the similarity ends.While the Edge Crush Test box offers less weight Cartons with strong stacking qualities, the Mullen Test box is better suited for protecting heavy contents. Because the design of the linerboard cannot be changed, the Mullen Test box should always be used when in doubt. For instance, the medium or flute paper cannot be less than 23# per square inch basis weight when used for 200# Mullen Test linerboard, which must be manufactured of 42# per square inch basis weight paper.

When And What Box To Use?

Use a single wall 200# test box when the combined weight of the box and its contents is less than 65 lbs. This weight restriction is suitable for a masterpack box or many light-weight products packed neatly in a row or stack inside a box. We advise a 45-pound weight restriction or upgrading to a 275-pound test single wall box if one big item is to be sent in a single wall, 200-pound test box. Just use your common sense, and always err on the side of caution.

Box Style

Regular Slotted Carton (RSC)

The most popular boxes are RSCs, sometimes known as shipping boxes. They typically feature four flaps on the top and bottom and one “Manufacturer’s Joint” where the side walls are sealed. They are typically Kraft brown in colours. The majority of packaging applications benefit greatly from this design.

Multi – Depth Carton (MDC)

The same box shape as an RSC but with horizontal Scores (creases) down each of the four side walls at various depths. You may pack a box with greater depth flexibility thanks to this function. A box with many depths can contain multiple boxes.

Half-Slotted Carton (HSC)

The Half Slotted Carton is an RSC variant with just one pair of flaps. The box may glide over an object since the opposing side is fully open. Imagine using a box that has been flipped over so that the flaps are on top. Typically, the covered object is fastened to a pallet or other surface that acts as a separate bottom.

Full Overlap Slotted Carton (FOL)

All “length” flaps on a full overlap slotted carton are also the same width as the box. In order to strengthen and protect the top and bottom, the flaps actually fold over one another.

Five Panel Folder (FPF)

When completed, a five-panel folder really resembles a shallow-depth box. The top and end panels of the one-piece box overlap one another. The practical design is also cost-effective.

Snap-Bottom Carton (SBC)

Available with a tuck-in top or top flaps in the RSC fashion (shown). additionally known as a “auto bottom” box. For rapid construction, the box’s bottom simply snaps into place without the use of tape. Lightweight items are best suited.

Full Telescope Design Carton (FTD)

A two-piece box that has a top that is separate and covers a bottom tray.

Half Telescope Design Carton (FTD)

Two half-slotted cartons, one slightly smaller than the other so it can fit inside the other. you the option of adjusting the box’s height or length to suit your needs. Ideal especially for bulky, hefty things.

Two-Piece Carton With Separate Lid (CSL)

Die-cut box with an open top and a tray-style cover. Similar to a File Storage Box, but without the hand slots on either end.

Double Cover Carton (DC)

This box is commonly used for tall or large, heavy objects. The Double Cover Carton is a three-piece box made up of a four-panel Tube that acts as the side panels and two interchangeable trays that function as the top and bottom of the box.

One Piece Folder (OPF)

The One Piece Folder, also known as “Bookfolds” or “Bookwraps” features a flat bottom with two small flaps at each end creating the sides and two longer, broader flaps making the front, back, and top of the box. Depending on the depth of the contents, the broader flaps either overlap or meet at the top. A bookfold often has several depths of scoring (creases) on its four panels. Books and photographs are packaged in shallow depth using one-piece folders. Typically made from white board.

Mailer-Style Boxes (MSB)

A single-piece, tape-free Die-Cut box that is put together. On the sides and bottom of the box, there are two layers of protection. With a tuck-in top or a locking cover, sometimes known as a “cherry lock” design, are the two most prevalent designs available. (Check out examples.) Mailer-Style Boxes are incredibly robust and can endure the worst handling during shipping.

Bin Boxes (BB)

An additional one-piece die-cut box that may be put together without glue or tape. Bin Boxes, also known as shelf boxes for components and other tiny goods, feature an open top so you can see inside and reach in. width, length, and depth measurements Storage space may be greatly increased by using these long, thin boxes. available in four different lengths and several widths

Divider Bins (DB)

Smaller open-top bins are called Divider Bins. They are typically used with bin boxes to make several sections inside a bin box.